Project Portfolio

Take a look at some of the projects I've been working on!

You'll find a few personal projects, product designs, and tech demos that I wanted to show off and talk about. Let me know if you have any questions.

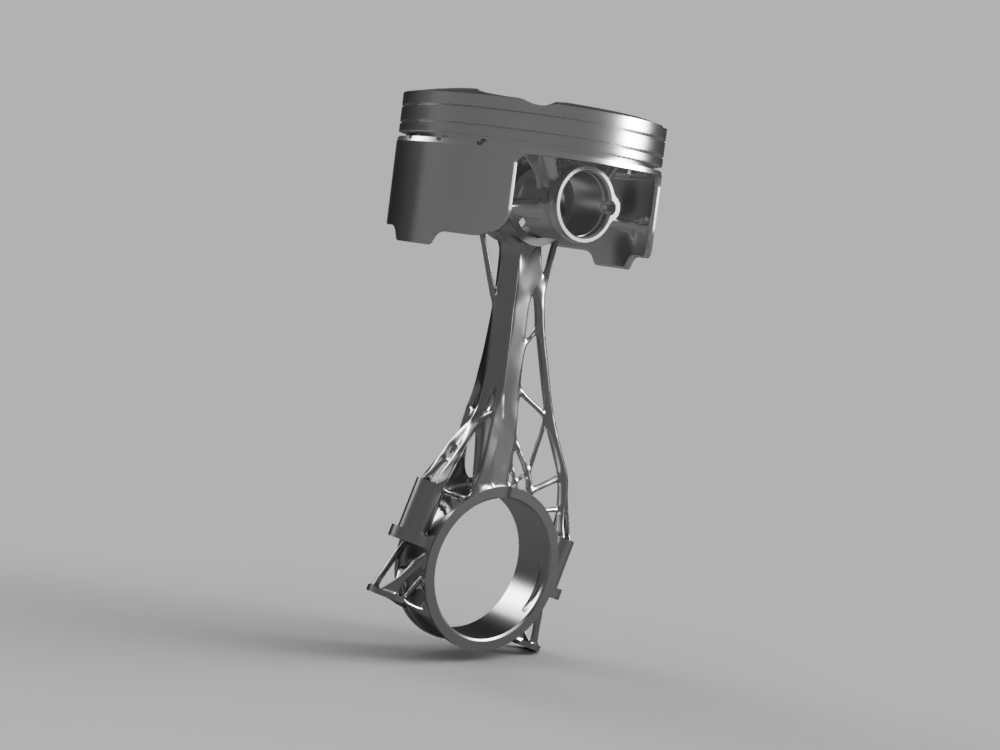

I made this Subaru Forester piston using Fusion's generative design software. The final product was printed in Aluminum and Steel. I think this was the coolest looking thing I've ever made.

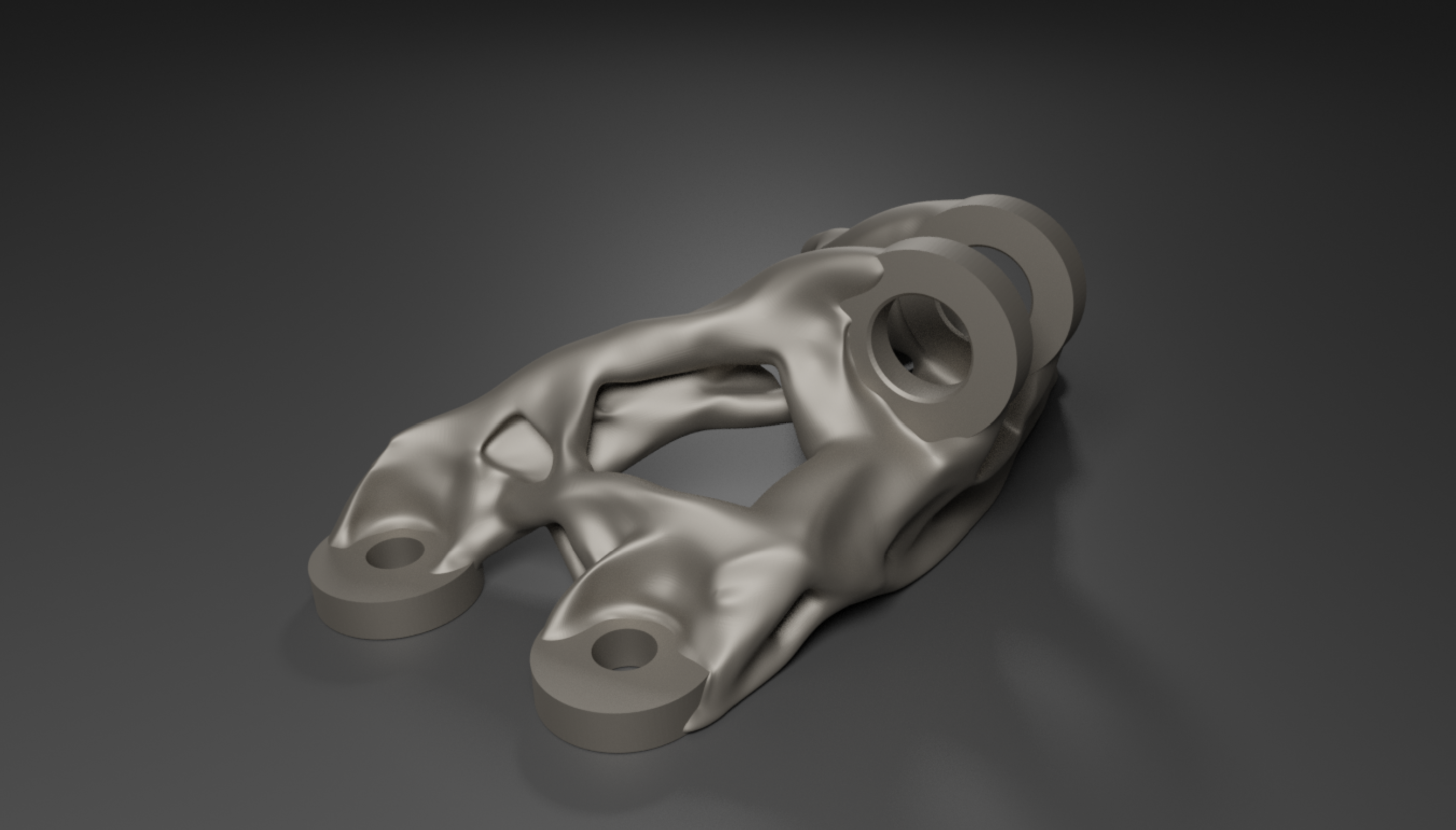

I made this jet engine bracket using Fusion's generative design software. The final product was printed in Titanium.

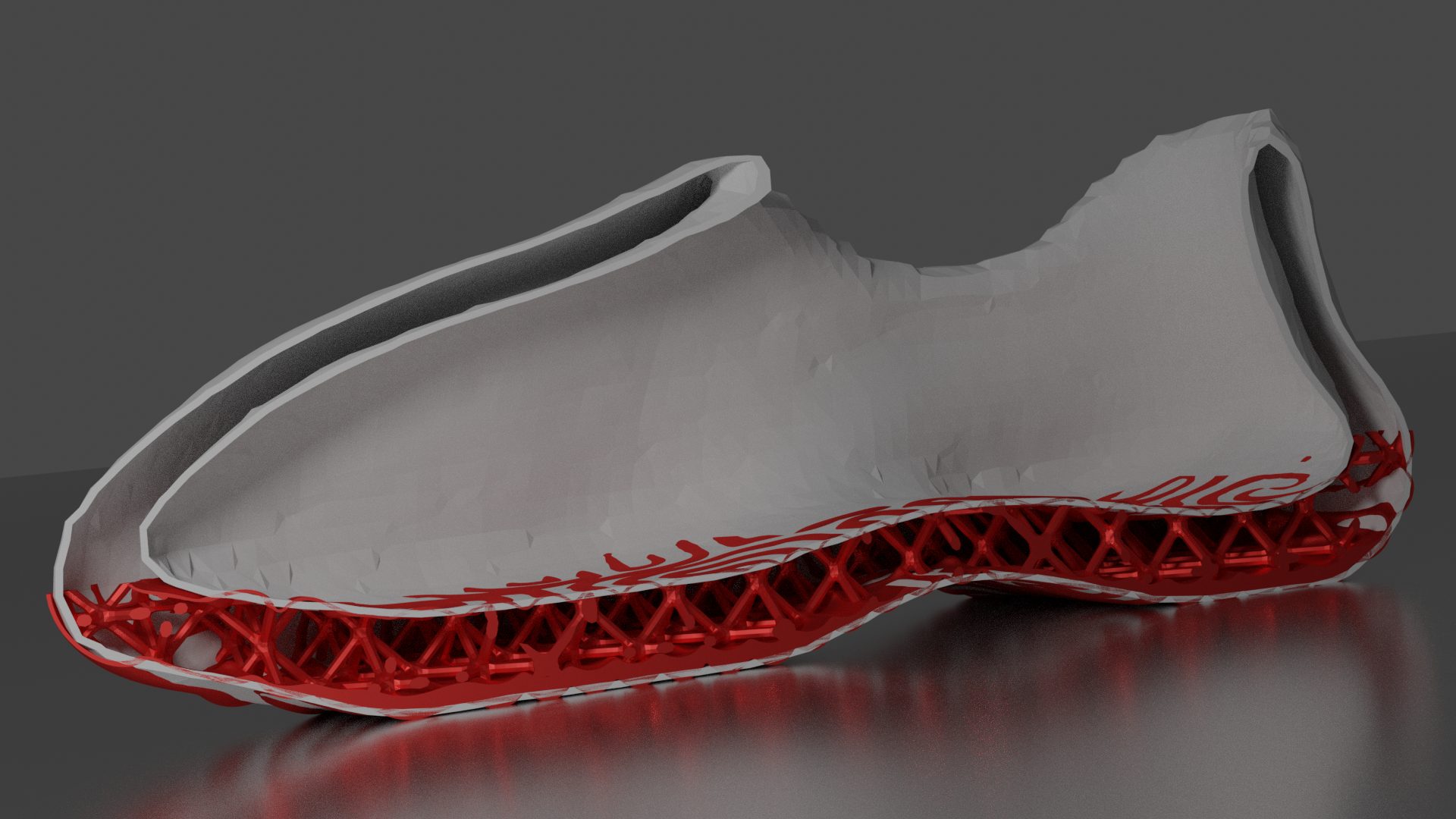

I made this inner lattice structure to support the sole of the shoe and keep it from collapsing. Lattice structures like these have a wide array of applications and I intend to discover more of them. This was printed in TPU.

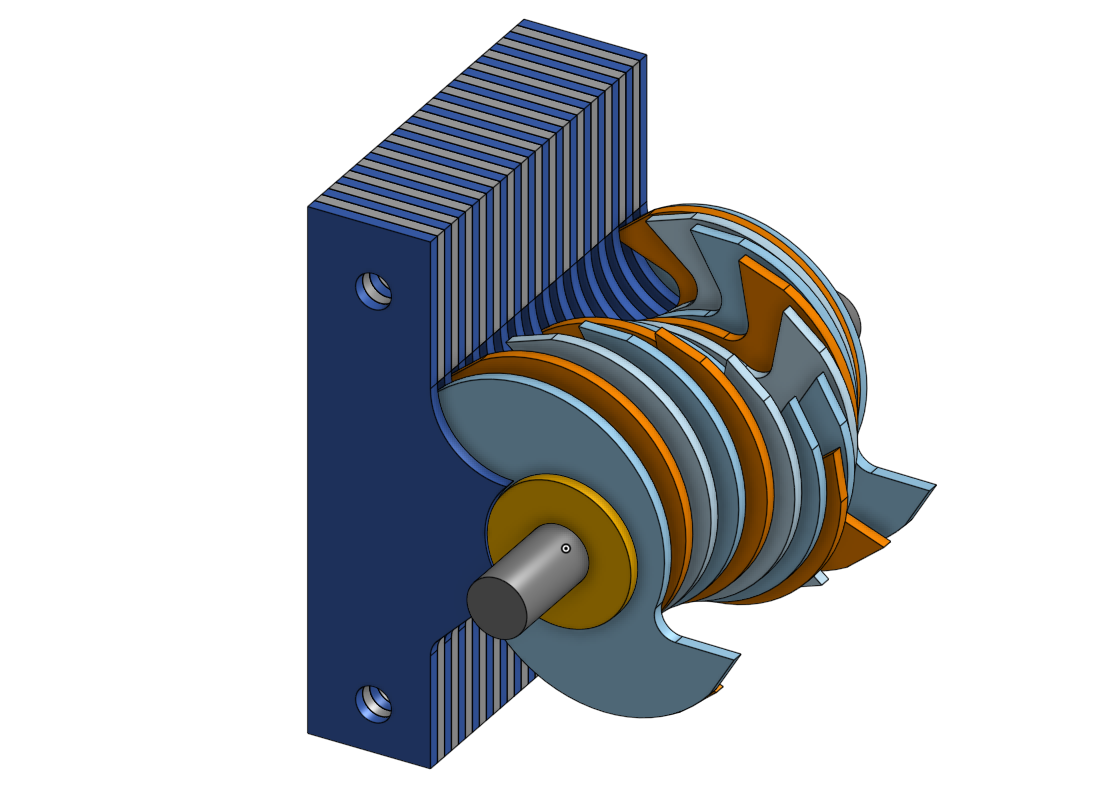

This was a design for a small format shredder to use in recycling plastics. It was designed to be laser cut, but was sadly never produced.

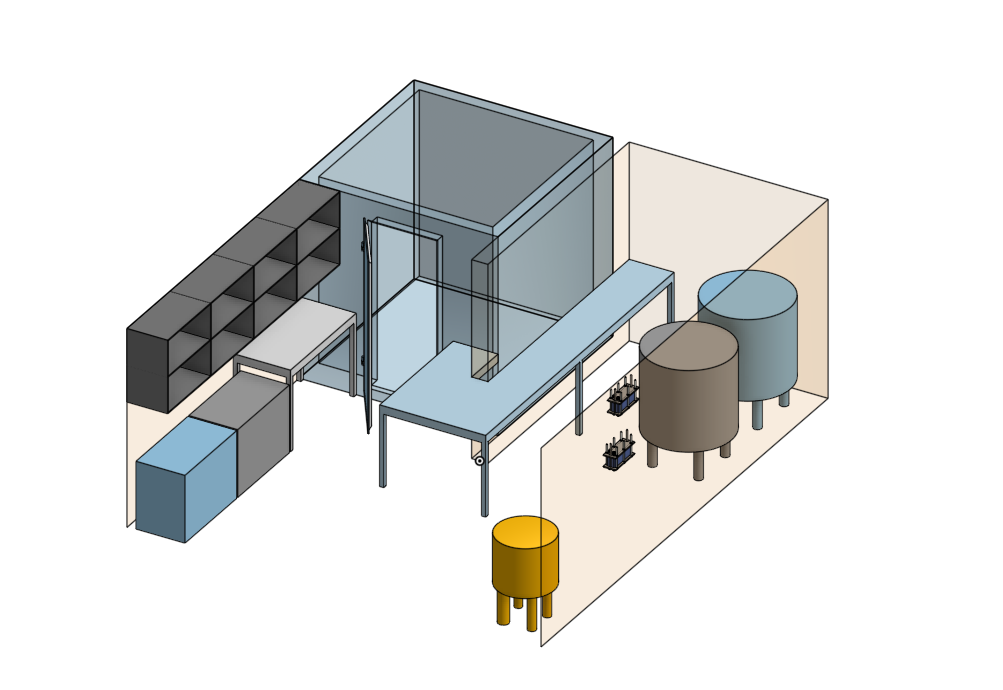

A layout for a small-scale yogurt production facility designed to operate out of two deployable shipping containers whithout access to infrastructure. This has been in use, for several years now, but some of the more interesting features never made it into the unit.

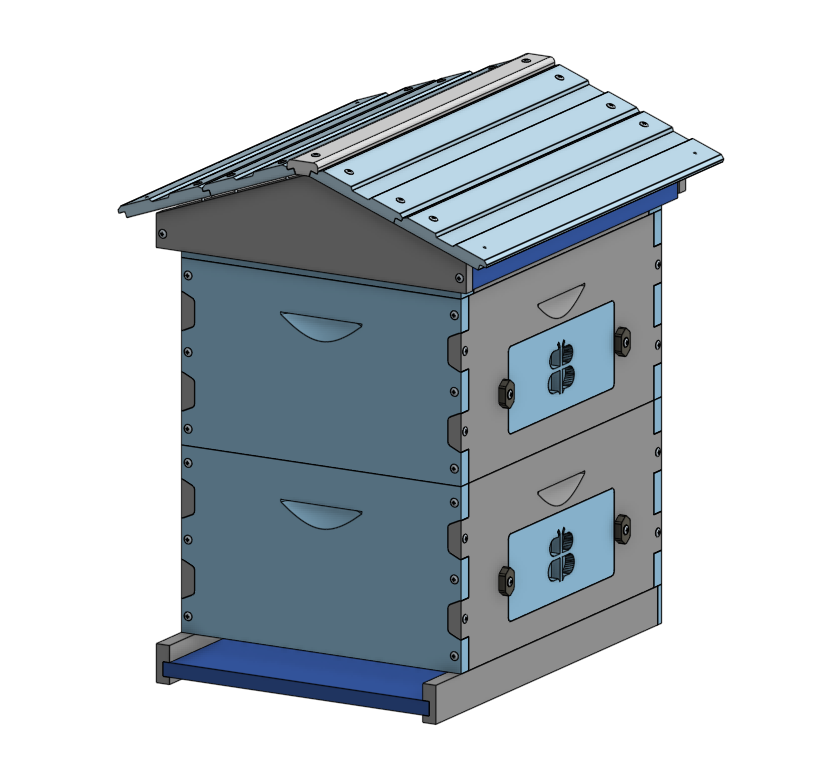

Redesign of a flagship product, a high quality Langtroth Hive, for a local beehive manufacturer. I optimized for larger production volumes and produced the manufacturing procedures for this and the following two projects.

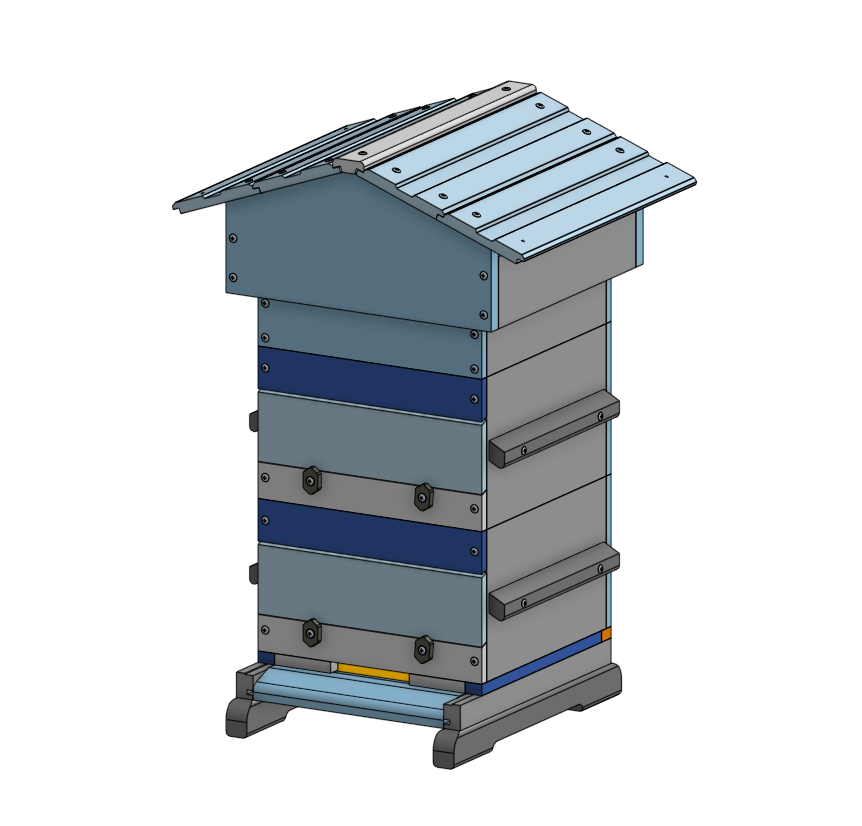

A Warre Hive; another redesign for the same company. This one was tricky because I had never built one of the hives myself. I had to spend extra time communicating with the shop team to make sure it was a feasible design.

This was a massive overhaul of their top-of-the line product, the Top Bar hive. I completely changed the design, optimizing it for CNC machining and standardizing their product line. I learned so much from this project and it was incredibly satisfying to see it go into production.

If I could go back and try again, I would simplify one of the lower assemblies. It worked well enough, but there were too many similar parts and too many trigky steps where assembly could go wrong. Maybe someday...

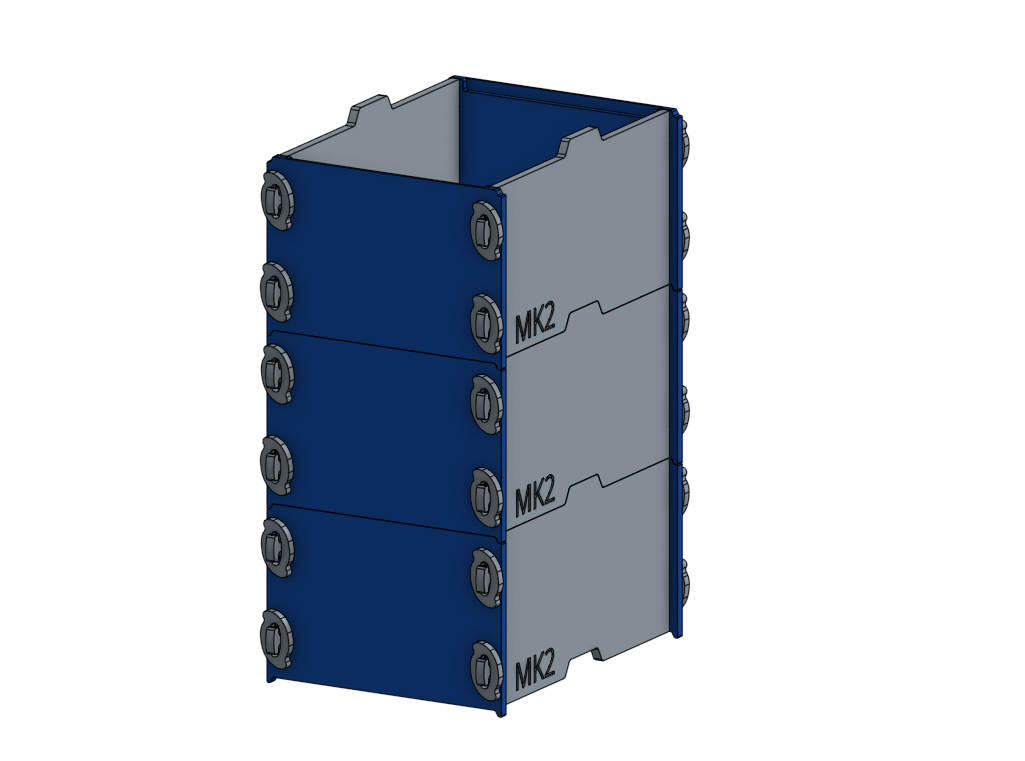

This was a personal project I started, exploring the idea of an open-source, CNC-router friendly line of beehive designs. The idea is that anyone could take a sheet of plywood to their local makerspace and have a full behive without the need for hardware.

I made a few proof-of-concept models, but eventually dropped the project. I would like to finish it at some point, if only so I can have a cool looking beehive in my yard.